Why Thickness Matters for Metal Fabrication Projects

Sheet metal fabrication requires a wealth of knowledge and expertise, as well as equipment. The thickness of sheet metal in fabrication is essential and selecting the right thickness is core in a project’s success.

This month’s blog at MK Steelworks Ltd looks at the importance of thickness in sheet metal fabrication. For more details, call us in Nottingham, call us on 08000 141424.

How is Sheet Metal Thinned?

The thickness of sheet metal ranges from 0.5mm to 6mm and can be thinned to the desired size before use. There are several methods used to thin metals, including:

- Rolling

- Deep Drawing

- Ironing

Rolling passes the sheet metal through rollers to reduce thickness. For steel, hot rolling can reduce the thickness of the metal whereas cold rolling is ideal for precision applications as there is no shrinkage during the process.

Deep drawing is the process in sheet metal forming by a mechanical punch. This is typically to change sheet metal into cylinders or hollow vessels.

Ironing thins the areas of sheet metal and is an incredibly useful method in achieving a uniform thickness.

To find out more about MK Steel Works please call on 08000 141424 or use our contact page.

Accreditations

MK Steelworks Ltd

We have a wealth of knowledge and expertise within the fabrication industry. We can advise on your project requirements and offer workmanship of the highest quality.

Areas We Cover

MK Steelworks Ltd

Since the company’s inception, we have continued to grow our operation throughout the UK and Ireland and have delivered a multitude of complex projects across a range of sectors.

Projects

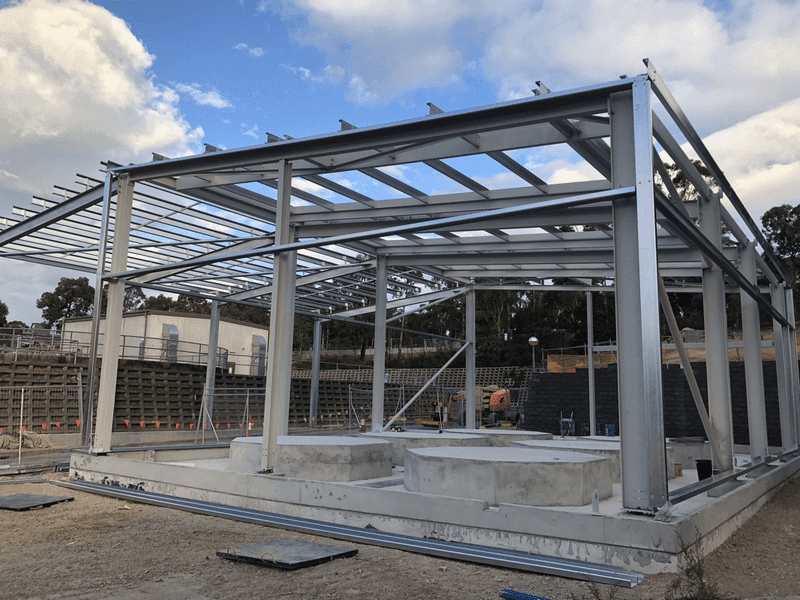

MK Steelworks Ltd

Working with domestic, commercial and residential clients, we have a wealth of expertise, take a look for yourself by viewing our previous projects.

MK Steelworks Ltd

The Advantages to Thin Sheet Metal

Thin sheet metal is used for many architectural metalwork applications. This is due to its strength, durability and life expectancy. It can be used for many projects, including benches, handrails, bus stops and more. Additionally, it is lightweight.

Another advantage to thin sheet metal is that it requires very little upkeep. It reduces the cost long-term and provides a reliable solution.

Choosing the Right Sheet Metal

The thickness of the sheet metal depends on what it will be used for. It is important to choose the correct specifications for optimum functionality, efficiency and durability.

One important factor is flexibility. More rigid products will require thicker sheet metal. However, objects that require curves are better constructed from thinner metal. In addition to this, there are many other factors to consider, including the weather and temperature.

Contact Form

Contact MK Steelworks Ltd

For further information about our steel fabrications, contact MK Steelworks Ltd. Call us in Nottingham on 08000 141424. Alternatively, you can make an enquiry through our contact form.

You can find us here.